General repair shops should embrace the latest developments and position themselves to grow profitability through the industry's increasing reliance on ADAS. By offering calibrations, general repair shops will create an additional and extremely reliable revenue stream.

Hunter Industry Insights

Finding the Best ADAS Calibration Equipment for Your Shop

Considering ADAS calibrations? We've got you covered. Here we'll discuss all the important factors in researching ADAS equipment and how innovative and easy-to-use Hunter products can help your shop build a profitable ADAS business. When you're ready to learn more, contact your local Hunter team for detailed product information, onsite demos and pricing options.

ADAS growth

Take control of ADAS

ADAS is the fastest-growing automotive market segment, forecasted to reach $65.1 billion by 2023 at a CAGR of 9.7

The amount of ADAS-equipped vehicles is skyrocketing, with more than 60 million now and increasing each year

The demand for calibrations continues to grow, with at least one in three of these vehicles requiring calibration following common services, such as a wheel alignment

What is ADAS?

ADAS Calibrations

Top 9 things to consider

How to define good ADAS calibration tools and equipment?

Accuracy & Precision

It is vital that ADAS calibrations have precise measurements to ensure the safety of a customer's vehicle. Calibration equipment should take all the ambiguity out of calibrations.

Speed & Efficiency

Does the equipment integrate OE procedures to simplify set-up and calibration processes, allowing for greater speed and instilling customer confidence that the work was peformed properly?

Vehicle Manufacturer Approval

Has the equipment been tested and approved by any third party, such as the vehicle manufacturer? Ensure your equipment meets these OEM requirements.

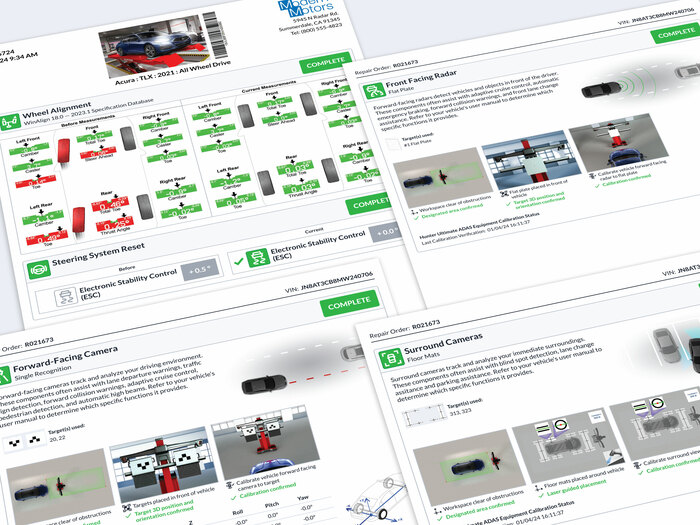

Verfication & Documentation

ADAS equipment should provide detailed documentation and reports for insurance purposes and to reassure customers that the calibration was completed correctly and their vehicle is safe to drive.

User Interface

Is the equipment easy to use? Does it provide logical, straightforward instructions for shop technicians? Look for live camera-guided interface to ensure accurate step-by-step procedures.

Integration & Compatibility

Ensure that the equipment is engineered to work with a wide range of vehicle makes and models, ensuring maximum efficiency for your shop.

Training & Support

What degree of training and support does the equipment manufacturer offer? Is there detailed instruction to guide technicians from start to finish?

Reliability

Invest in dependable and durable products that meet industry standards and ensure calibrations are done correctly the first time.

ROI

Consider your return on investment by calculating how quickly your equipment can pay itself off based on the number of calibrations your shop can perform.

ADAS Overview

Hunter University

This course is intended to expose the learner to the basics of ADAS technology within the automotive industry. Register now

Shop types

How do shops benefit from performing ADAS calibrations?

General repair shops

Collision shops

Collision repair facilities are perfectly situated to benefit from the steady stream of vehicles needing ADAS calibrations. Keeping this work in-house, instead of subletting, can dramatically drive profitability.

Calibration centers

Calibration centers will have an increasing role in the developing ADAS calibration marketplace. To maintain this position, calibration centers will need to invest in high-quality training and efficient, durable equipment to keep up with demand.

Automotive dealerships

ADAS technologies are evolving rapidly with frequent advancements and new functionalities introduced on a yearly basis. Dealerships able to keep up will drive customer retention by providing maintenance, repair and ADAS services at a single location for years to come.

Tire dealers

Tires are the backbone of vehicle safety. ADAS calibration are usuallly required whenever suspension work or wheel alignment occurs. By including ADAS services, tire dealers can capture this profitable work while the vehicles are right there in the shop.

Government & education

Government and educational facilities have a stake in ensuring transporation and public service vehicles are operating in a safe manner.

Features of ADAS equipment

What are the most important ADAS equipment features?

Alignment and static ADAS calibration

The ultimate space-saving solution is to perform ADAS calibrations and wheel alignment all in the same bay.

Mobility

Look for a portable design that allows the equipment to be conveniently moved to other working locations as needed.

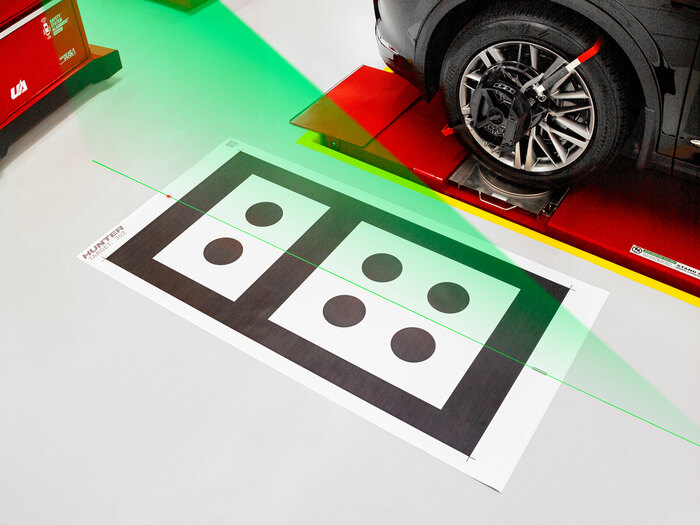

Laser-guided target placements

Spot-on, laser-guided target placement eliminates tedious manual efforts and saves enormous time.

Error-proof steps

Error-proof monitoring of steps and position confirmation keeps technicians on track.

Full documentation

Equipment should offer a full and easily accessible document report that records confirmed placements and work completed in printed and digital formats.

Full around-the-vehicle

Does the system quickly define target placements for static procedures?

Static requirements

What are the requirements for static ADAS calibrations?

Floor space

Moderate lighting

Flat floor

Wall color

Floor space

It's a popular misconception that ADAS calibrations require huge floor space. The majority of forward-facing calibrations can be performed in almost any shop.

- Minimum — 25 ft. x 34 ft.

- Recommended — 30 ft. x 45 ft.

- Optimal — 40 ft. x 60 ft.

Moderate lighting

- The calibration area should be well lit with evenly diffused and distributed light.

- Cover any windows with direct sunlight during calibration.

- Avoid any directional lighting around the vehicle during calibration.

Flat floor

- The floor of the calibration space should be level, or ADAS equipment that compensates for non-level floors should be used. Learn more about Ultimate ADAS

- To evaluate a floor, take transit measurements at anticipated wheel footprints.

- The difference between the side-to-side and front-to-back measurements should be no more than 0.4 inches (10 mm).

Solid, neutral wall color

- The area outside of the calibration area should be clear of geometric patterns.

- Floors and walls should be one solid, light neutral color.

- During recalibration, the surroundings should be clear.

How much space is required?

The majority of forward-facing ADAS calibrations can be completed within 16.5 feet or less.

Dynamic requirements

What are the requirements for dynamic ADAS calibrations?

ADAS calibration tool

The most basic requirement for dynamic ADAS calibrations is having a reliable calibration tool.

No shop space required

One of the biggest perks of dynamic ADAS calibrations is that no shop space is necessary.

Nearby highway

A nearby highway with clear lane markings and little traffic so vehicles can reach speed without obstructions will be most convenient.

Browse ADAS equipment

Ultimate in-house ADAS solutions

New

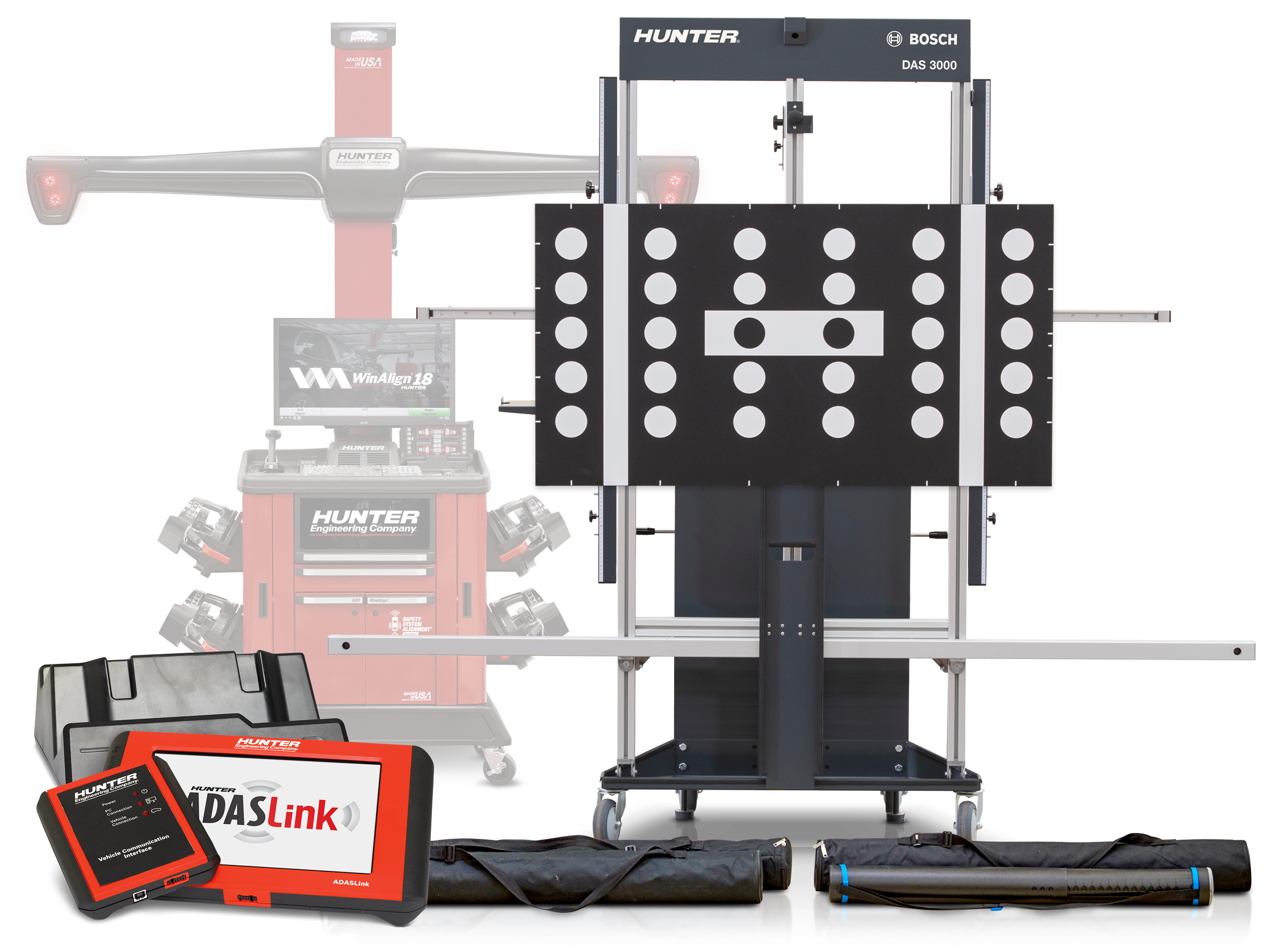

Ultimate ADAS

Laser-guided ADAS calibrations and wheel alignment and ADAS in one

Wheel alignment and all static ADAS calibration are done in the same bay, with the same equipment.

Learn more

Made in the USA

3-year warranty

Local sales team

Already have an alignment system?

Excellent. You've already taken your first step toward ADAS calibrations. Now it's time to add dynamic calibration with ADASLink®.

Ready to perform dynamic ADAS calibrations?

ADASLink® supports Ultimate ADAS and the DAS 3000 fixture.

Additional options

ADASLink® + DAS 3000 fixture

OptionalAll ADASLink® features

Static ADAS calibrations

Extensive OE target support

Guided positioning with ADASLink®

Includes first year of static calibration software

ADASLink® scan tool

OptionalDynamic (driving) ADAS calibrations

Full diagnostics with pre- and post-scan

WinAlign® software integration

On-screen step-by-step procedures

FCA secure gateway compatible

CodeLink®

StandardSteering angle sensor resets

WinAlign® software integration

Wondering about your return on investment?

Learn how quickly today's ADAS calibration investment will pay itself off.

FAQ