- Ergonomic “pick and place” wheel lift for complete control of heavy assemblies

- Lighted lower roller makes bead breaking and lubrication easier

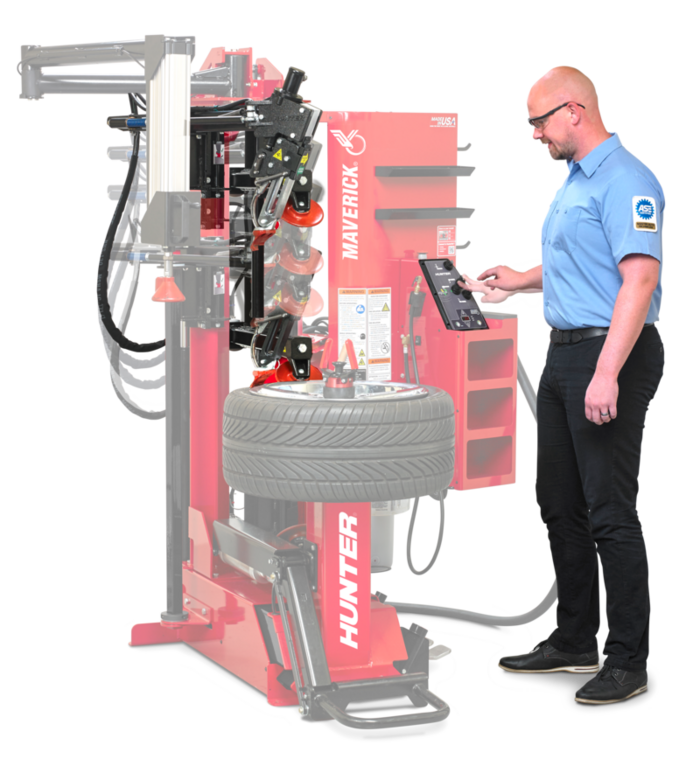

Tyre Changer

Hunter Maverick®

The Maverick® technician-focused tyre changing machine designed and built in the USA provides fully variable hydraulic control and unique features that allow a safe and easy tyre changing process.

Maverick® Tyre Changer

/

Maverick® at-a-glance

Fully variable controls give the technician complete authority in the tyre changing process

Uniquely designed SmartSet® toolhead is easy to use

Hydraulic speed and accuracy are the best in the business

Smart safety features protect the wheel, tyre and technician

InflationStation™ fills tyres quickly to correct pressure

Designed and built in the USA using the finest US and global materials

“Maverick® has your back”

Choose from three different models, each made in the USA, featuring fully-variable hydraulic controls and unique safety features. Available in red or black.

TCMPRO

Added features

TCMW

Added features

- Compact wheel lift that is perfect for extreme wide wheels and can double as a tyre lift when servicing heavy assemblies such as 19.5s

TCM

Base model includes

Premium features like a SmartSet® leverless head, proportional controls, and InflationStation™ make tyre service smooth and fast.

Go “PRO” for maximum benefits

Features available on TCMPRO models

Ergonomic “pick and place” wheel lift

Lift and tilt heavy assemblies and 19.5s up to 79 kg. in one smooth motion. Lift holds position while elevated and lowers automatically.

Lighted lower roller

Significantly improves visibility for easier bottom bead breaking and lubrication. Light activates automatically during lower roller operation, with a customizable timer shut-off.

The Maverick® Pro tire changer builds upon the popular original

The Maverick® Pro tire changer takes the popular original Maverick® and adds an ergonomic pick-and-place wheel lift and an under-wheel light for bottom bead illumination.

Using is believing for Kennedy Tire Arnold

Kennedy Tire mounts and balances “a lot of 35s, which are heavy,” Jason says, “and they put a lot of wear and tear on us.” But with the Maverick’s responsiveness and ease of use, “At the end of the day, you feel the difference.”

The Hunter Maverick® is designed to give techs complete control

Reflecting user feedback, the Maverick® is designed for technicians, combining the convenience of hydraulic movement with the speed of manual operation.

The Maverick® Tyre Changer: Advanced clamping operation

Watch the advanced operation techniques for effectively clamping and mounting large reverse drop center and 19.5-inch large-bore assemblies.

The Maverick® Tyre Changer: Standard operation

See a demonstration of Maverick®’s demounting and mounting functions, use the joystick control, and hands-free walkaway inflation with InflationStation™.

Take control of tyre changing with the new Hunter Maverick®

Precision, power and control. That’s what technicians want in a premium tyre changer, and that’s exactly what Hunter Engineering has delivered in the Maverick®.

Gain complete authority in the tyre changing process

Technician-focused, responsive controls

- Fine-control or fast on-demand

- Hydraulic precision easier than air controls

- Ergonomic for all-day use

- Excellent tactile feedback — one-finger control for all functions

Articulating leverless system

Tool head simultaneously adjusts with base to the wheel size

Unique toolhead design focuses on efficiency and safety

SmartSet® leverless advantages

- Indicator notch shows proper set height

- Demounting hook deploys to catch and lift bead

- Eliminate lever damage risk to the operator or rim

- Safely and easily service clad and raised spoke wheels

Built-in features protect the wheel, tyre and technician

Intelligent safety and productivity

- Monitors roller and hook positions to prevent unintended wheel contact

- Logic automatically “homes” rollers, head, and wheel lift for hands-free productivity

- Allows customization of travel and rotate speeds, ramp rate, and more

RollerLock™ clamp

Safe & quick

- Ball bearing threads clamp quickly and tightly

- Lever handles multiply clamping force

- Smooth surface prevents center bore damage

Bead press arm

Powerful assistance

- Simple joystick control

- Handles the toughest tyres

- Arm rotates with wheel

- Lifting ledge allows pusher to be used as a bead lifter

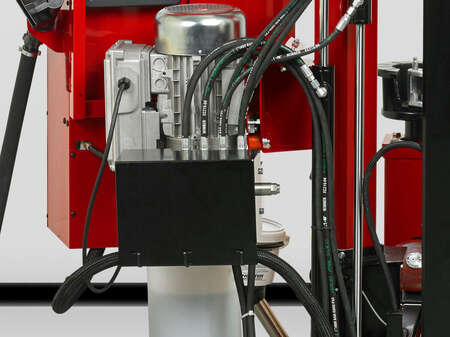

Hydraulic power

Full control & power

- 0-17 RPM fully variable speed forward and reverse rotation

- Each tool can be moved and held as needed

- No erratic movement when loaded and unloaded

Underside mirror

Accessible viewing

- Correctly position bottom roller

- Fixed location never needs adjustment

- "PRO" model features under wheel light for better visibility

Wheel Lift

Optional

- Lifts the heaviest assemblies with ease

- Auto-lowering saves time and prevents damage

- Configurable pedal operation

Flange plate kit

Optional

- Ideal for plastic clad wheels or reverse wheels

- Offers maximum protection

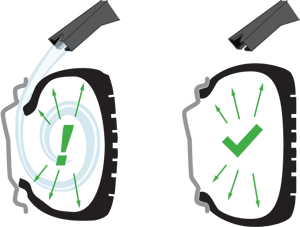

Inflate all tyres to their correct pressure

Automatic mode

Automatically inflates tyres to desired pressure 33% faster than standard inflation systems, allowing technicians to walk away while inflating

Pressure settings

Adjust pressure settings to specify the correct air pressure

Blast inflation

Directs a large blast of air for tough bead seating

Match-mount tyres when paired with a balancer

Made in the USA

The Maverick® tyre changing machine is proudly made in the USA using the highest-quality materials sourced domestically and internationally.

Set the wheels in motion

Schedule your free on-site demonstration today.

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Specification Sheets

-

Accessories

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.