- 7200 kg Capacity

- 4953 mm Two-wheel alignment wheelbase

- Flush-mount installation only

- PowerSlide® and InflationStation™ capable

Maximum Productivity, Minimum Space

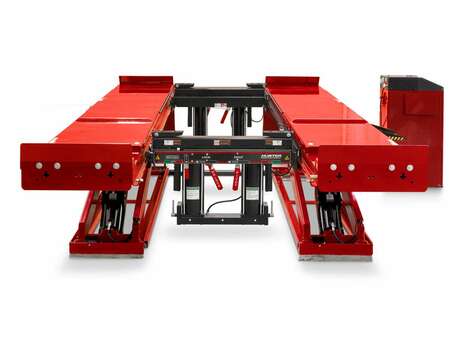

SCISSOR ALIGNMENT LIFTS

Maximum Productivity, Minimum Space

Hunter's automotive scissor lift family offers four capacities and several wheelbase lengths to meet virtually any need. Hunter vehicle scissor lift racks feature low drive on heights for all models, or even popular flush mount configurations. Add InflationStation™, PowerSlide®, and AlignLights options to really ramp up productivity.

New harsh-duty options available for high road salt/brine use applications.

FEATURES AT-A-GLANCE

- Open-front and rear access

- Stainless steel turnplates standard

- Built-in slip plates standard

- Two moveable worksteps standard

SPECIFICATIONS AT-A-GLANCE

-

4500 - 7200 kgCapacity

-

SWING AIR JACKSOptional

-

610 mmWide runways

-

4216 - 4953 mm2-Wheel Alignment Wheelbase

Hunter Scissor Alignment Lifts

/

PRODUCT FAMILY AT-A-GLANCE

RX72

7200 kg Capacity

RX63

6300 kg Capacity

- 6300 kg Capacity

- 4623 mm Two-wheel alignment wheelbase

- Surface-mount installation only

- PowerSlide® and InflationStation™ capable

RX55

5500 kg Capacity

- 5500 kg Capacity

- 4547 mm Two-wheel alignment wheelbase

- Flush- or surface-mount installation

- PowerSlide® and InflationStation™ capable

RX45

4500 kg Capacity

- 4500 kg Capacity

- 4216 or 4547 mm Two-wheel alignment wheelbase

- Flush- or surface-mount installation

- PowerSlide® and InflationStation™ capable

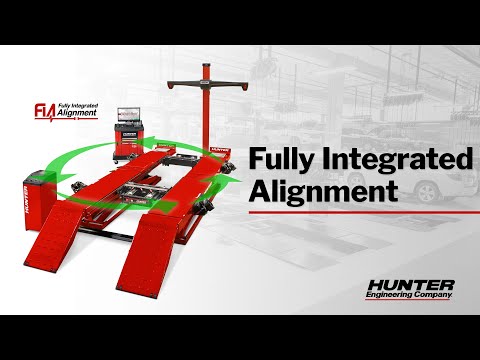

Streamline the process with Fully Integrated Alignment (FIA)

Eliminate errors

Automates technician tasks, like locking and unlocking turnplates, so critical steps aren’t skipped, preventing poor alignments.

60% Faster

Complete alignments faster with Hunter's synchronized wheel alignment machine and alignment rack.

WinAlign® Console

Guides technicians step-by-step, automates turnplates and slipplates, and communicates directly with the lift to set tire pressure.

Automatic Functions

Turnplates and slip plates auto-lock, and inflation station automatically inflates tires.

Precision Cameras

- Four high-resolution cameras

- Measurements are taken automatically once the fourth target is installed

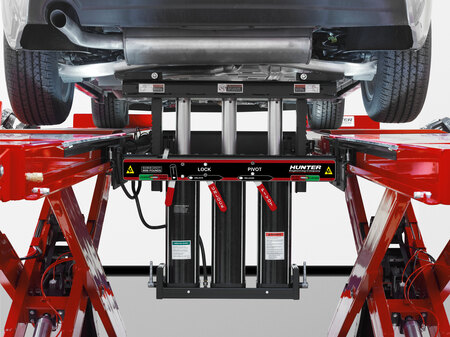

Auto-locking turnplates & slipplates

Auto-lock saves time and trips around the vehicle

Inflation Station

Patented

- Automatically inflates all four tires simultaneously

- Automatically records starting and final pressures

- Hose recoils to keep work area clear

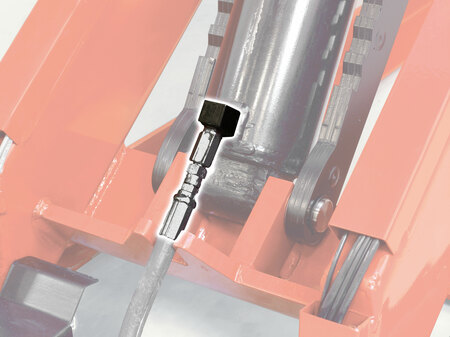

PowerSlide® System

Patended

- Slipplates and turnplates automatically lock and unlock at appropriate times

- No more struggles with turnplate & slipplate pins

Hunter Scissor Alignment Lifts: Standard Operations

See a quick demonstration of the safest and most efficient methods of operating the Hunter RX Scissor Lift Rack with a vehicle loaded on the runways.

Fully Integrated Alignment Equipment from Hunter Engineering

Hunter's fully integrated alignment system reduces the technician's trips around the vehicle, and greatly reduces trips to the alignment console.

Hunter Alignment Rack: Precision at Its Best!

Hunter Alignment Rack: Precision at Its Best!

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

Flush-Mounting

Eliminate ground clearance concerns, and give your workspace a premium appearance.

Extra-Wide Runways

Drive-on ease, up to vehicles 2337 mm wide, wheelbase choices allow for fits for every shop.

Fast Descent

Reduced lowering time by 50% with soft landing ensures safety.

Swing Air Jack Equipped

Equip with optional high-capacity swing air jacks—an industry standard with unmatched height, reach and durability.

Built-in Rear Slip Plates

2235 mm to 4013 mm long for 4-wheel alignments on any vehicle.

Stainless Steel Turnplates

Stainless Steel Turnplates Standard, for a lifetime of easy and accurate alignments.

Louvered Approach Ramps

High traction prevents wheel spin. Better than diamond plate or abrasive finish.

Sixteen Position Locks

Fine mesh locks insure levelness and safety.

Electronic Level Control

Keeps runways level at all time shuts down with obstruction.

Hydraulic Safety Fuses

Instantly shutdown in event of hose failure.

Optional Alignlights

See where you work. Lights shut off automatically when rack is lowered, light when raised.

Air Line Kit

Air supply to jacks and auxiliary ports standard.

Two Movable Worksteps

Sturdy, lightweight and lock into multiple convenient locations (not suitable for flush lifts).

Hunter Scissor Lift Features

Discover how your Hunter Scissor Lift can benefit your shop.

Our fully inegrated alignment system (FIA) automates turnplates, slip plates, and tire inflation while WinAlign® guides every step. Upgrade your scissor rack with seamless alignment capability today.

Optional Harsh Duty

Racks with Hunter's Harsh Duty feature enhanced corrosion protection for those regions with high road salt and brine solution usage. Available only on IS and PS model lift racks.

Zinc-rich primer

Zinc-rich primer on runways, ramps and bases provide a second layer of protection

Stainless Steel Slipplate Tops

Corrosion-resistant stainless steel slipplate tops and complete turnplates

Epoxy-Sealed Joints

Epoxy-sealed joints and seams prevent salt seepage between adjoining pieces of metal

Polymer Components

Polymer slipplate balls and retainers will not corrode

Threshold Cover

Pre-galvanized and powder coated threshold cover

SET ASIDE A BIT OF SPACE IN

YOUR SHOP FOR PRODUCTIVITY

SPECIFICATIONS

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

GALLERY

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Specification Sheets

-

RX45 Surface-Mount Specifications (English International)

View

-

RX45 Flush-Mount Specifications (English International)

View

-

RX45 Flush-Mount with Inflation Station Specifications (English International)

View

-

RX45 Long Flush-Mount Specifications (English International)

View

-

RX45 Long Flush-Mount with Inflation Station Specifications (English International)

View

-

RX55 Surface-Mount Specifications (English International)

View

-

RX55 Flush-Mount Specifications (English International)

View

-

RX55 Flush-Mount with Inflation Station Specifications (English International)

View

-

RX63 Specifications (English International)

View

-

RX72 Flush-Mount Lift Specifications (English International)

View

-

RX72 Flush-Mount with Inflation Station Specifications (English International)

View

-

RX45 Surface-Mount Specifications (English International)

View

-

Accessories

FAQ

EXPLORE MORE