Beginning in 1946 with World War II veteran and founder Lee Hunter, Jr., and continuing through today with Vietnam War veteran and chairman Stephen F. Brauer, Hunter Engineering has been veteran-owned for its entire history and is among the largest veteran-owned businesses in St. Louis, MO.

Our History

Hunter Engineering, founded by Lee Hunter, has a rich history built on innovation and excellence.

Hunter History

Lee Hunter & Hunter Engineering

Hunter Engineering Company owes its beginnings to a discharged automobile battery. Lee Hunter Jr., a 23-year-old St. Louis architecture student, found himself frequently confronted with car battery failure in his Packard convertible.

When experts said it couldn't be done, Lee Hunter invented a way to quick charge automobile batteries. He then went on to build a highly successful company to manufacture and sell his other inventions that would soon after revolutionize the automotive service industry.

Today, Hunter Engineering Company designs, manufactures and sells a wide range of auto service equipment for a global market. Hunter products include PC- and Windows®-based wheel alignment systems, computerized wheel balancers, versatile tire changers, on- and off-car brake lathes, feature-packed vehicle lifts and money-saving inspection equipment.

1930s

Kwikurent

1936

Kwikurent, the world’s first rapid battery charger, reduced charging time from 24 hours or more down to less than an hour, eliminating the need to remove the battery from the car. It was a revolution in the industry that sold as fast as the company could build them.

Rocket Special

1938

Set out to shrink the design into a more compact form, Lee Hunter intruded the Rocket Special that included a dual-charge test meter that analyzed voltage gravity in 10 seconds and an 100-ampere output for maximum charging speed. It also operated on a more widely accessible 110-volt circuit.

1940s

Return home

1946

After serving in the U.S. Army Corps of Engineers and the Ordnance Corps during World War II, Lee Hunter returns home to St. Louis to open Hunter Engineering Company on Hunter Avenue in Ladue, Missouri.

Tune-In balancer

1946

The Tune-In balancer, Hunter Engineering's debut product, is a revolutionary on-the-car balancer and Lee Hunter invention.

First brochure

1949

Form 8-T, produced in June of 1949, is the company’s first product brochure.

1950s

Sales & service team

1950

Lee Hunter began assembling what would later become the largest dedicated sales and service team in the tire service equipment industry.

Sales meetings

1952

Sales Representatives become a driving force behind Hunter Engineering’s growth. Sales meetings and group photos become a Hunter tradition.

GM approval

1953

General Motors opens a plant in St. Louis to build the Corvette. This custom installation ensures every Corvette wheel is balanced by Hunter.

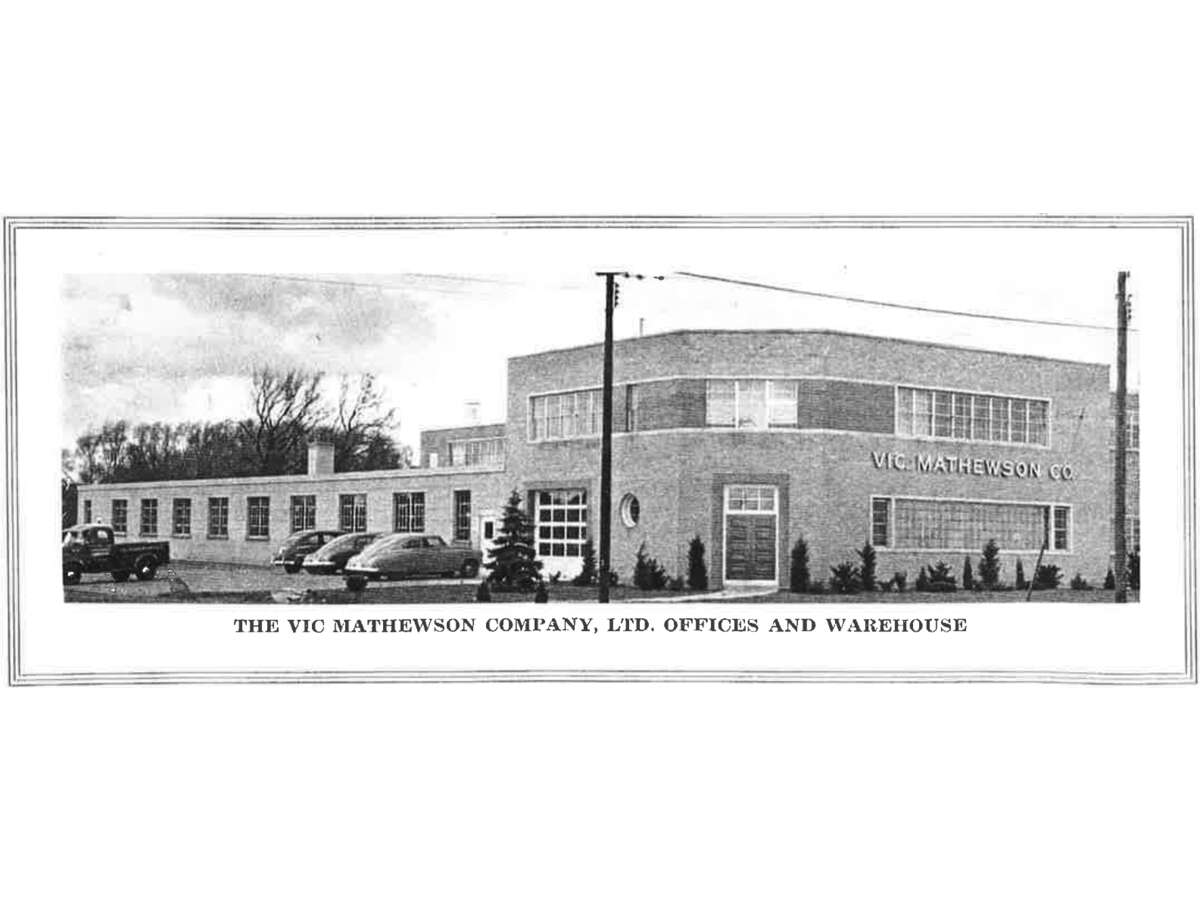

The Vic Mathewson Distributor

1950's

The Vic Mathewson Company Limited, Canada's largest automotive distributor, was Hunter's Canadian distributor and representative in the 1950's.

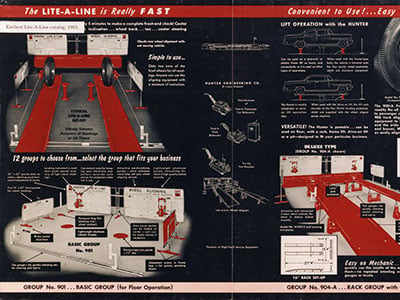

Lite-A-Line

1955

Hunter Engineering develops the Lite-A-Line wheel alignment system. It soon becomes the industry standard.

More configurations

1955

Hunter develops multiple configurations of the Lite-A-Line system.

1960s

Hunter staff

1960

Hunter Engineering has a small but growing staff. Pictured here, the Engineering, Advertising, and Inspection departments all work side-by-side.

"Happy Hunter"

1962

“Happy Hunter” was a staple in early Hunter advertising and training films.

Sales conventions

1962

The 1962 Annual Sales Convention was held in St. Louis.

Relocation & expansion

1964

Hunter outgrows its original facility and relocates to a 23-acre campus next to St. Louis Airport. The location features new offices and manufacturing complex more than triple the size of the original.

Ford partnership

1964

After rigorous testing, Ford Motor Company names Hunter its sole supplier of alignment and balancing equipment.

Heavy-duty alignment

1967

Hunter alignment systems expand to cover heavy-duty applications.

Trade shows

1967

Hunter continues to expand its presence at top industry trade shows in the United States and Canada.

Compute-A-Line

1969

The F-60 and F-70 Compute-A-Line systems were the industries first dynamic service aligners. Adjustments could be made without moving the vehicle and while the wheels are turning.

1970s

Hunter Training Center

1973

The Hunter Training Center opens adjacent to the company headquarters.

Rapid Series balancers

1974

Hunter introduces the Rapid Series balancers, signaling the dawn of dynamic, off-car wheel balancing.

Ride Perfection Center

1974

Hunter’s Ride Perfection Center in operation. The RPC relieved portions of the sidewall to reduce radial force variation.

Advanced alignment systems

1975

The original Lite-A-Line system (left) is joined by the S5 Electron-A-Line, Tune-A-Line II, Autron-A-Line, and the Lite-A-Line II. Advanced Wheel Alignment systems become Hunter’s core focus.

Durant, MS manufacturing

1976

Hunter opens a manufacturing facility in Durant, Mississippi, to accommodate demand for a growing product line. The area bordered in red shows the layout of the original 1976 facility.

S6 Electron-A-Line

1977

The S6 Electron-A-Line featured electronic camber, caster and toe measurements.

S7 Electron-A-Line

1979

Hunter’s S7 Electron-A-Line introduces the thrust-line principle to wheel alignment which becomes the foundation of modern four-wheel alignment technology.

1980s

Hunter Automotive Limited

1980

Hunter incorporates its Canadian operations into Hunter Automotive Limited to handle product distribution throughout Canada.

Hunter Canada moves

1980

Hunter Canada moves to Markham, ON, doubling warehouse space to 12,000 SF and adding a parts room, classroom, offices and training bay.

Leadership change

1981

Stephen F. Brauer appointed President, marking the first leadership change since Lee Hunter founded Hunter Engineering. Brauer guides the company into a period of rapid growth with the integration of new computer technology.

A111 wheel aligner

1982

The first CRT display wheel aligner allowed technicians to see measurements on screen.

Sales & service meetings

1983

A growing field organization attends the 1983 National Sales and Service Meeting from September 21-24.

Raymond, MS manufacturing

1984

Construction begins on the new production facility in Raymond, MS, which opens the following year.

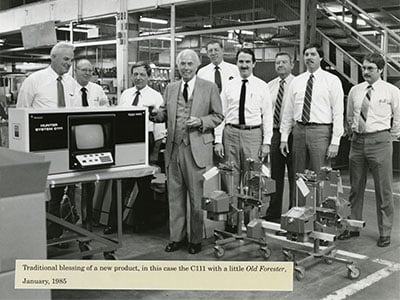

C111 production blessing

1985

The C111 starts its production run in January 1985 with the aid of a little “Old Forester” — the traditional blessing of a new product.

Hunter Canada moves to Richmond Hill, ON

1986

Hunter Canada moves again to Richmond Hill ON, increasing space to 15,400 SF, upgrading Power Bay and increasing warehouse and office space.

Strong partnerships

1986

Lee Hunter meets with Hunter’s Japanese distributor, Iyasaka Ltd., maintaining a strong partnership that began almost a quarter-century before, in the 1960s.

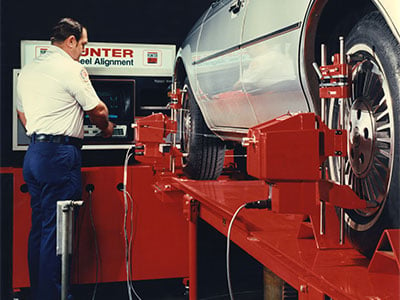

Wheel-mounted sensors

1987

This first wheel-mounted sensor (a predecessor of the future DSP series sensors) proves to provide fast, accurate alignment readings.

RL lift rack

1988

The RL rack featured fully floating rear slipplates, air line kit, retractable work steps and built-in turnplate pockets.

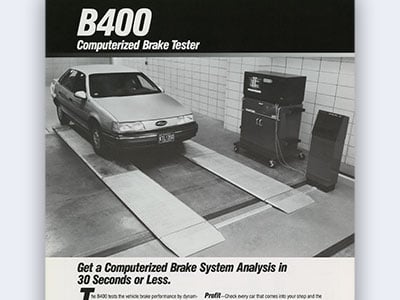

Brake testing

1989

The B400 computerized brake tester measures brake performance with a 4-minute drive-through process.

1990s

Hunter Service Center

1991

The Hunter Super Service Center opens and serves as the main distribution center for replacement parts in the U.S.

Windows® partnership

1992

WinAlign® recognized as the first Windows®-based vehicle alignment system.

Automotive Hall of Fame

1992

Lee Hunter inducted into the Automotive Hall of Fame where he shares the spotlight with industry giants such as Henry Ford, Louis Chevrolet, Walter P. Chrysler and Soichiro Honda.

DSP9000 balancer

1993

The DSP9000 balancer is the first to use digital signal processing for unparalleled accuracy.

Truck Safety Center

1993

The Truck Safety Center expands research, product development and technician training for heavy-duty vehicles.

P211 alignment system

1994

The P211 is the first PC-based alignment machine, featuring Windows®-based WinAlign® software and DSP200 series sensors.

TC325 tire changer

1995

The TC325 features Hunter exclusive “tulip” clamping system, ergonomic design and three-point articulated mounting arm – features found on many Hunter tire changers to this day.

DSP200 series sensors

1995

The DSP200 and DSP250 series wheel alignment sensors become the industry standard, featuring infrared beams that link together to produce accurate alignment measurements.

BL500 brake lathe

1996

The BL500 is the first brake lathe to offer Digi-Cal technology which instantly measures drum or rotor dimensions to help technicians determine total indicated runout.

411 series alignment system

1997

The 411 Series Alignment System features industry-leading technology including the most advanced personal computing hardware.

GSP9700 balancer

1997

The GSP9700 offers a simulated road test to diagnose and solve non-balance related wheel vibration issues, transforming this wheel balancer into a wheel diagnostic center.

DSP400 camera sensors

1998

DSP400 digital imaging sensors feature durable, easy-to-handle reflective targets. Four cameras in the aligner tower measure the position and orientation of each wheel-mounted target which instantly provide initial wheel alignment measurements.

1998

The TC3250 features a tilted ergonomic design. With the addition of the “Plus” device, this versatile machine becomes Hunter’s most popular EMT approved tire changer.

RM lift rack

1999

The innovative design of the RM lift rack allows easy service access through its split front design.

2000s

Four-Post lift racks

2001

L421 (14,000 lb.) and L424 (16,000 lb.) alignment racks are introduced featuring longer slipplates than previous generations.

RX9 scissor lift rack

2001

The RX9 alignment rack offers several popular features including an open front and rear design for easy service access, extra-wide 24" runways, integrated air line kits, and the option to mount the rack flush with the floor.

GSP9712 christening

2002

Hunter Chairman, Steve Brauer, leads the traditional christening for the first GSP9712. The revolutionary tire balancing system features industry firsts such as StraightTrak® which measures and corrects tire pull issues.

Hunter Canada moves to Newmarket, ON

2002

Hunter Canada moves to Newmark, ON.

Hunter Deutschland GmbH

2002

Hunter Deutschland GmbH opens. The office and training facility near Munich offers German car manufacturers the same engineering support available to U.S. manufacturers.

811 alignment system

2003

The 811 aligner, combined with DSP600 digital imaging sensors and WinAlign® 7.0, features increased productivity, profitability and value. This system leads the industry for five years.

DSP500T sensors

2004

Designed specifically for heavy-duty applications, the DSP500T series alignment sensors offer measurement accuracy and repeatability never before seen in the heavy-duty industry.

OEM approvals

2004

Hunter Engineering’s state-of-the-art digital imaging alignment systems gain approval by BMW, Daimler Chrysler and the Volkswagen Audi Group (VAG). Hunter remains the only alignment supplier with all three German automaker approvals.

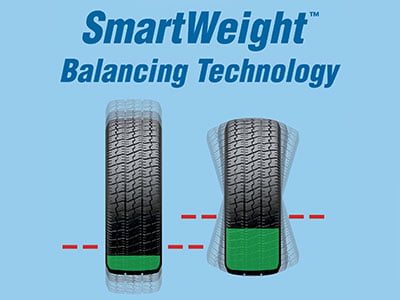

SmartWeight®

2005

Revolutionary SmartWeight® Balancing Technology is introduced. This patented balancing method improves wheel balancing results while minimizing the amount of corrective weight applied by the operator.

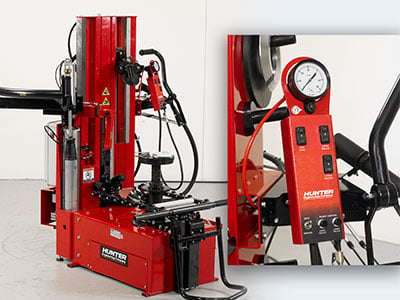

TCX500 series tire changers

2010

The TCX500 family of tire changers are introduced. This group of table-top tire changer offers coverage for passenger car to medium duty vehicles. This line of changers will go on to become an industry staple and Hunter best-selling series.

GSP9200 balancer

2006

The GSP9200 balancer is introduced. Though intended as a compact model, it is packed with advanced features including SmartWeight® laser line weight placement, auto double Dataset® arms, Spindle-Lok®, rim scan and Quick-Thread®.

Durant, MS 30 years

2006

Durant, Mississippi, reaches a milestone and celebrates 30 years of fabricating and assembling Hunter lift racks.

GSP9700 improvements

2007

The third generation GSP9700 improves on Hunter’s most popular model by featuring improvements such as a Linux operating system, color LCD monitor, thumb drive data port and the ability to have a custom logo on the welcome screen.

WinAlign® 10.0

2007

Using the new WinAlign® 10.0 software, the HawkEye® high definition digital imaging wheel alignment system is introduced with smaller, lighter sensors designed for speed and efficiency.

Auto34 tire changer

2008

The Auto34 introduces a new level of control to tire changing with a simple control panel. Technicians are able to perform all operations without the traditional lever.

SmartWeight® balancer

2009

Hunter formally introduces the SmartWeight® balancer — a highly productive balancer designed for every shop. Fully-integrated with SmartWeight Balancing Technology® it also features many powerful options including a wheel lift, AutoClamp, a top dead center laser system, and a printer.

Four-Post improvements

2009

The L441 and L444 four-post lift racks provide 18,000 lbs of lifting capacity and the option of an open- or closed-front designs.

2010s

WinAlign® improvements

2010

WinAlign® 11.1 features improvements such as new CodeLink® printouts and support for the DSP700 sensors. The TouchRemote® app for the iPhone® adds a new dynamic to WinAlign®.

TCX500 series tire changers

2010

The TCX500 family of tire changers are introduced. This group of table-top tire changer offers coverage for passenger car to medium duty vehicles. This line of changers will go on to become an industry staple and Hunter best-selling series.

HawkEye Elite®

2011

HE421 HawkEye Elite® with TD targets introduced. True three-dimensional targets that eliminate metal to metal contact as well as the need to carefully center the target. This system proves faster, lighter, more durable and changes the way shops align vehicles.

Hunter China

2011

Hunter China opens a wholly owned subsidiary off ice in Beijing China. The Chinese market is in a period of rapid growth and expansion.

Quick Check®

2012

Hunters Quick Check® system offers fast and accurate alignment checks right from the service drive. This system becomes one of Hunter Engineering's bestsellers and in record time.

RX lift rack improvements

2012

The RX series of racks expands with the introduction of the RX16. The surface mount version sits at only 9” when lowered but with the innovative Power-Up feature, the rack changes it lifting point allowing it to maximize capacity.

DSP700T sensors

2013

DSP700T sensors are introduced to the Heavy-Duty market. These sensors allow for all three axles to be measured at the same time. Designed to mimic the accuracy and convince of the passenger car system, the Heavy-Duty world now has a lightweight, fast and accurate equivalent.

Raymond, MS expansion

2014

Hunter’s Raymond, MS manufacturing plant expansion adds 66,000 square feet to include a state-of-the-art electronics facility to produce sophisticated electronic assemblies for many Hunter products.

Revolution™ tire changer

2014

The Revolution™ is the industry's first reliable, computerized and automatic tire changer. The Revolution™ uses an automated process for all tire and wheel combinations which turns all technicians into experts. It has the distinction of being the worlds first UL Listed tire changer and was completely designed and built in the USA.

Hunter Canada

2014

With the tremendous growth in the Canadian market Hunter Canada moves into its new facility. The building features state conference rooms as well as a complete Power Bay modeled after the St. Louis, MO facility.

Quick Tread®

2015

Tire health took center stage in 2015 with the introduction of Quick Tread®. The system scans all four tire in seconds and creates a 3-D model. The imaging from the model provides a true tire health report for customers.

SEMA Show

2016

Hunter Engineering became the largest non-OE exhibitor at the SEMA Show with a 7,000 square foot booth staffed by over 100 HQ employees and members of Hunter's field organization.

Road Force® Elite

2017

The Road Force® Elite, uses patented Hunter vision technology to automatically determine wheel dimensions and wheel runout measurements. GM announces the Road Force® Elite as essential equipment for use in service facilities in the U.S.

AutoComp Elite®

2017

The AutoComp Elite® introduced patented Automatic Compensation technology and an intuitive touchscreen interface. It also gained OE approval at an unprecedented rate.

Autonomous features

2018

The Revolution™ WalkAway™ allows for 80-second autonomous operation during the bead breaking and demounting process, and offers time saving of 25% or more when paired with wheel balancing.

Unmanned inspection

2019

Quick Check Drive® provides unmanned alignment audit results with no stopping or labor required. Additional cameras can capture 40+ images per vehicle, protecting shops against mistaken damage claims.

2020s

BL Series bench lathe

2020

The BL Series bench lathe brings speed, precision and versatility to brake service, plus Anti-Chatter Technology to eliminate virtually all vibration buildup.

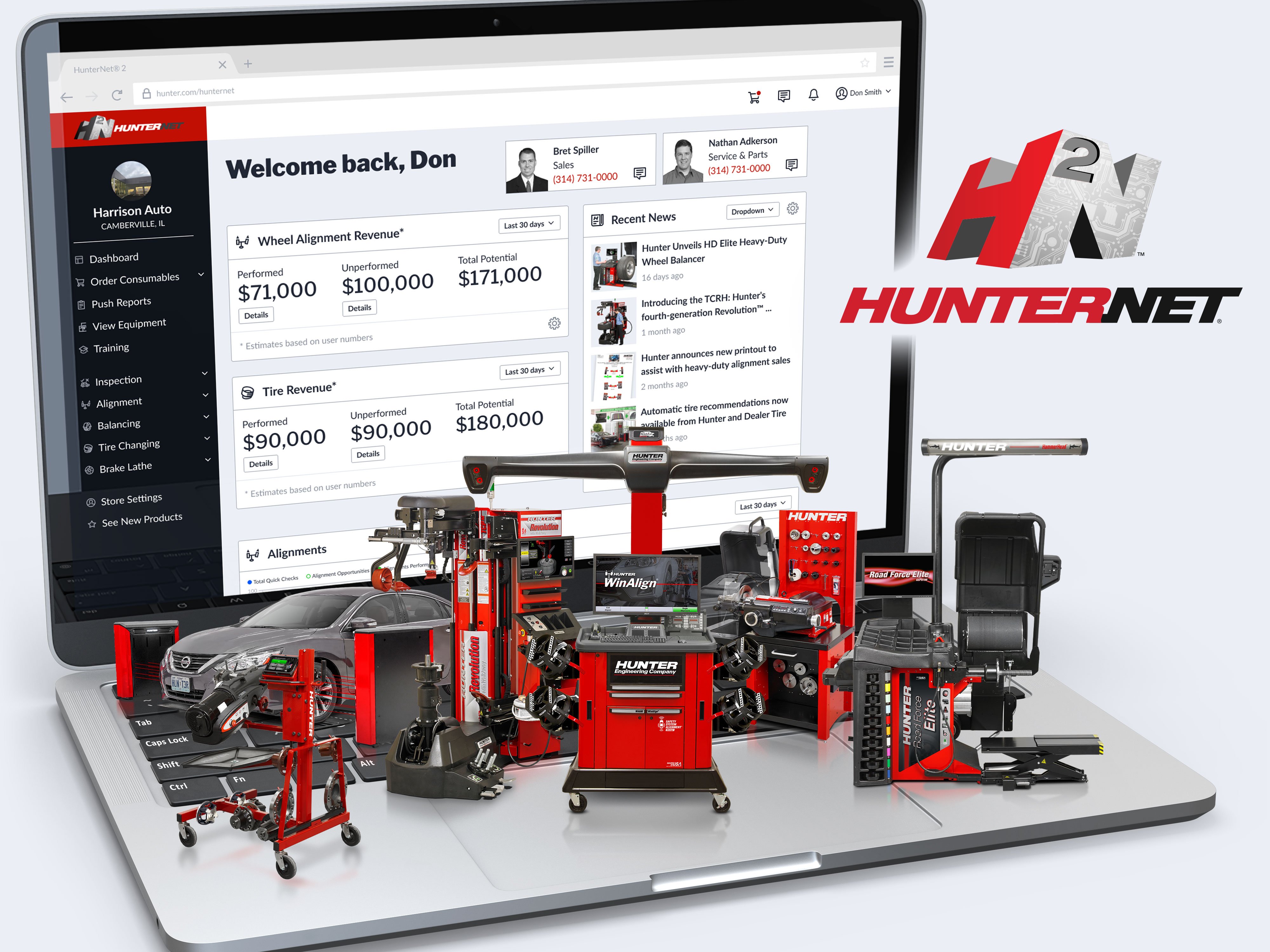

HunterNet® 2 portal

2020

The first of its kind in the industry, HunterNet® 2 online portal allows customers to track ROI, set goals, order consumables, and view and manage all of their Hunter equipment in real time.

75 Years

2021

Hunter Engineering celebrates 75 years of innovative, standard-setting products, built in the USA from a solid foundation of ingenuity, craftsmanship and service excellence.

ADAS calibration tools

2021

Hunter enters the booming ADAS market with the ADASLink® full-diagnostic scan tool, providing techs with quick access to step-by-step calibration procedures for more than 25 million vehicles.

Heavy-Duty Four-Post

2021

High capacity is the chief characteristic of the Heavy-Duty Four-Post alignment lift for commercial vehicles, offering 35,000-lbs. capacity and 300-in. wheelbase capabilities for safe and quick service.

Quick Check® Commercial

2021

Quick Check® Commercial makes Hunter the first global provider to introduce a touchless commercial inspection solution for measuring camber, total toe, tandem axle scrub and tire tread on all axles, on all trucks.

Maverick® Tire Changer

2022

The Maverick® premium center-clamp tire changer brings precision and power to a technician-driven machine, combining low-speed automatic functionality with faster, fully variable controls.

Mississippi Distribution Center

2022

Hunter opens a new 106,000-square-foot, 37-bay distribution center in Madison, MS, allowing production facilities more room and providing more efficient shipping to customers from a single location.

Hunter Deutschland Facility

2023

The 1150 spm facility in Puchheim, Germany contains a well-equipped, high-rack warehouse with European logistical support hub, training facility for service and user training, and lab area to support R&D cooperation with European OEs.

Ultimate ADAS™

2023

Ultimate ADAS ™ lives up to its name via innovative gimbal-mounted lasers that replace error-prone manual layouts and cut target placement time by 70 percent for some procedures.

HawkEye® XL

2023

The Hawkeye ® XL aligner's precise high-definition cameras provide extra-long-range sight, capturing measurements in four minutes and displaying live alignment readings for up to three axles at once.

Hunter Canada remodel

2025

Hunter Engineering Canada completes a remodel and redesign of its distribution center in Aurora, ON to significantly increase inventory capacity.